A voltage regulator module, often called a VRM, acts like a power manager for electronic devices, making sure each part gets the exact voltage it needs. VRMs convert higher voltage from a power supply into the lower, stable voltage required by sensitive components such as CPUs and GPUs. Nearly 80% of modern electronic devices rely on some form of voltage regulation, showing how essential a VRM is for reliable operation. Without a stable voltage, processors can suffer from performance issues or even physical damage, as seen in environments where voltage instability leads to high failure rates. Just as a water filter ensures clean water flows to every tap, a VRM ensures the right voltage reaches every important component.

Key Takeaways

-

A voltage regulator module (VRM) ensures electronic parts get the exact voltage they need to work safely and efficiently.

-

VRMs use components like MOSFETs, inductors, and capacitors to keep voltage stable even when power supply or device load changes.

-

Multiphase VRMs improve energy efficiency and reduce heat by sharing the power load across several phases.

-

VRMs protect sensitive devices like CPUs and GPUs from damage caused by unstable voltage and help maintain system stability.

-

High-quality VRM design and cooling extend device life and improve performance, making VRMs essential in computers, electric vehicles, and IoT devices.

What is a Voltage Regulator Module?

VRM Basics

A voltage regulator module, or VRM, is an electronic circuit that converts and regulates voltage for sensitive components like CPUs, GPUs, and RAM. Engineers also call these modules processor power modules or point-of-load converters. The main job of a VRM is to take a higher input voltage, such as 12 volts from a computer power supply, and deliver a lower, precise voltage that matches the needs of each component.

VRMs come in different types, each with unique strengths and weaknesses. The most common types in consumer electronics include linear regulators, low dropout (LDO) regulators, and switching regulators. Linear regulators, including LDOs, have a simple design and produce low output noise, making them ideal for noise-sensitive circuits. However, they lose efficiency and generate heat when the difference between input and output voltage is large. Switching regulators, on the other hand, use high-speed switching and energy storage components to achieve much higher efficiency, often between 80% and 95%. These regulators are common in devices that need to save energy or handle higher power.

Note: VRMs play a critical role in modern electronics by ensuring each component receives the correct voltage, which helps prevent overheating and damage.

Here is a comparison of common regulator types found in consumer devices:

| Regulator Type | Description | Common Use Cases in Consumer Electronics | Key Characteristics |

|---|---|---|---|

| Low Dropout (LDO) | A type of linear regulator that operates with input voltage slightly above output voltage. | Battery-powered devices, RF circuits, analog circuits, noise-sensitive sensors | Low noise, good ripple suppression, less efficient at high current, heat dissipation |

| Switching Regulators | Use high-speed switching and energy storage elements to convert voltage efficiently. | Smartphones, computer motherboards, portable electronics | High efficiency (80-95%), introduces EMI, requires filtering and careful layout |

| Buck (Step-down) | Switching regulator topology that reduces voltage from high to low. | Computer motherboards, smartphone main power supplies | Efficient step-down conversion |

| Boost (Step-up) | Switching regulator topology that increases voltage from low to high. | Camera flash drivers, LED backlight applications | Efficient step-up conversion |

| Buck-Boost | Switching regulator topology that can step voltage up or down depending on input voltage level. | Portable devices requiring flexible voltage regulation | Versatile voltage regulation |

Core Function

The core function of a voltage regulator module is to deliver a stable voltage to sensitive electronic parts, even when the input voltage or the load changes. A VRM uses a feedback control system to compare the output voltage with a reference value. If the output voltage drifts, the VRM adjusts its internal switches to bring the voltage back to the correct level.

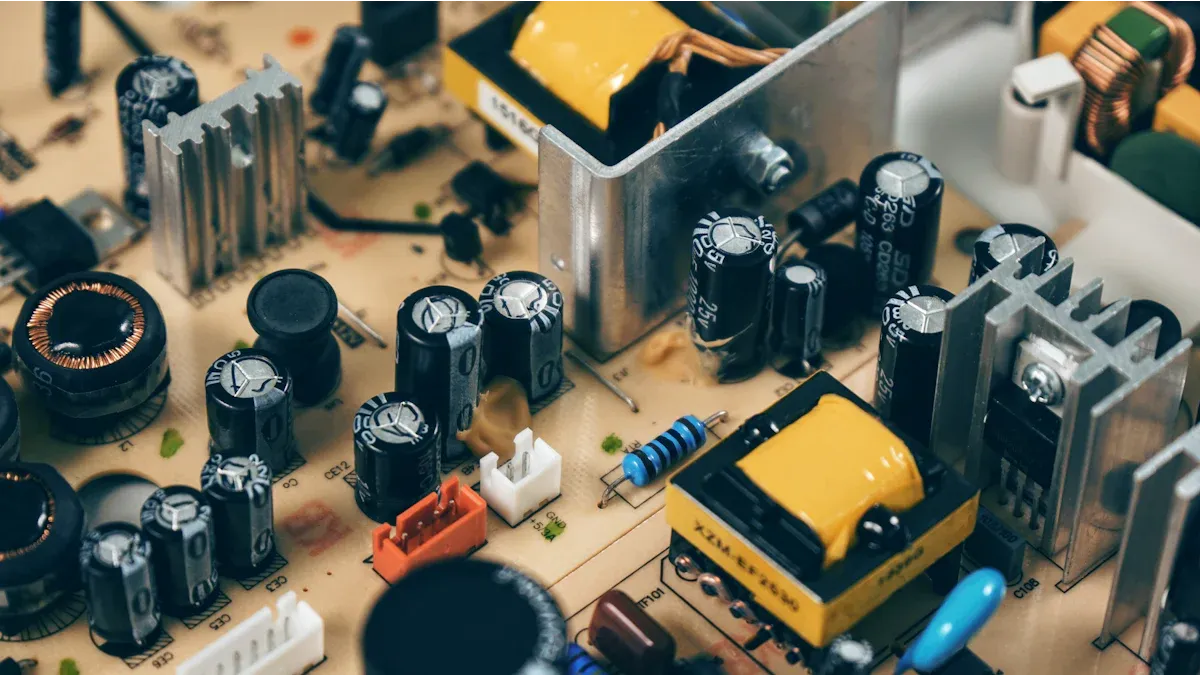

A typical VRM includes several key components:

| Component | Function |

|---|---|

| MOSFETs (High-side and Low-side) | Act as switches to regulate voltage by controlling current flow. High-side MOSFET connects input voltage; low-side MOSFET provides synchronous rectification to improve efficiency. |

| Inductors (Chokes) | Store energy in a magnetic field and smooth current changes, controlling the rate of voltage change. |

| Capacitors | Stabilize output voltage and handle dynamic power demands by smoothing voltage ripple. |

| Diodes / Synchronous Rectifiers | Manage flyback current when switches open, improving efficiency by redirecting current flow. |

| PWM Controller | Controls switching timing and duty cycle of MOSFETs using feedback loops to maintain stable output voltage. |

| Doublers | Used in some VRMs to increase the number of phases virtually, improving current sharing and reducing ripple. |

| Resistors and Driver Chips | Assist in controlling, monitoring, and driving the MOSFETs and other components. |

| VID Logic | Communicates with CPU for dynamic voltage scaling and adjustment. |

The VRM's feedback system works like a thermostat. When the output voltage rises above the target, the VRM reduces the current flow. When the voltage drops, it increases the flow. This constant adjustment keeps the voltage steady, which is vital for the performance and safety of CPUs, GPUs, and other sensitive parts.

-

A voltage regulator module maintains a constant output voltage, even if the input voltage changes or the device suddenly needs more power.

-

The VRM uses a reference voltage, an error amplifier, and a pass element (such as a transistor) to compare and adjust the output.

-

Inductors and capacitors act as energy buffers, smoothing out any sudden changes and keeping the voltage stable.

-

Modern VRMs often use buck conversion, which steps down voltage efficiently using switching transistors.

-

Multiphase VRMs split the load across several phases, reducing electrical stress and improving both efficiency and stability.

Tip: Stable voltage from a VRM protects sensitive electronics from damage and ensures reliable operation, especially in high-performance computers.

How VRMs Work

VRM Components

A VRM contains several important parts that work together to deliver a stable power supply. Each component has a unique job in the voltage regulation process. The main VRM components include inductors, capacitors, transistors, and controllers. These parts help the VRM convert the power supply voltage into the exact level needed by sensitive electronics.

| VRM Component | Role in Voltage Regulation Process |

|---|---|

| Inductor | Resists sudden changes in current, stores energy in a magnetic field, and releases energy to keep voltage steady. Controls the rate of voltage change and prevents spikes. Works with pulse-width modulation (PWM) to regulate average output voltage. |

| Capacitor | Filters voltage ripple and stabilizes output voltage. Provides extra charge during sudden power demands from CPUs or GPUs. Works with inductors to form the output filter, ensuring a low-ripple, stable power supply. |

| MOSFETs (Transistors) | Act as high-speed switches that control the flow of current. They turn on and off rapidly to manage how much energy moves from the power supply to the load. |

| Controller | Monitors the output voltage and adjusts the switching of MOSFETs. Uses feedback to keep the voltage at the correct level. Can be analog or digital, depending on the VRM design. |

Other supporting parts, such as resistors and driver chips, help control and monitor the main VRM components. Together, these parts allow the VRM to respond quickly to changes in power needs and keep the voltage stable.

Voltage Regulation Process

The voltage regulation process in a VRM uses a special circuit called a buck converter. Buck converters step down the power supply voltage to a lower level that matches what the CPU, GPU, or RAM needs. This process uses a combination of switching, energy storage, and filtering to create a stable power supply.

The buck converter mechanism works in several steps:

-

The high-side switch (usually a MOSFET) turns on, connecting the input voltage to the inductor. The inductor stores energy in its magnetic field, and the current through the inductor rises.

-

The high-side switch turns off. The low-side switch or diode conducts, and the inductor releases its stored energy to the load. The current through the inductor falls, but it never drops to zero in continuous conduction mode.

-

The inductor and capacitor work together to smooth out the current and voltage, reducing ripple and keeping the output voltage steady.

-

The controller adjusts the duty cycle, or the amount of time the high-side switch stays on, to regulate the average output voltage. This allows the VRM to respond to changes in load and input voltage quickly.

Inductors and capacitors play a key role in this process. Inductors resist sudden changes in current and store energy during the charging phase. They release energy during the discharging phase to maintain a stable output voltage. Capacitors filter out voltage ripple and provide extra charge during sudden changes in power demand. This teamwork ensures that the VRM delivers a stable power supply, even when the load changes quickly.

Modern VRMs use either analog or digital control methods. Analog voltage regulators use an analog feedback loop with error amplifiers to stabilize the output voltage. Digital voltage regulators replace the analog loop with an analog-to-digital converter (ADC) and a digital processor. This allows for higher precision control and real-time monitoring of temperature, input voltage, and output current. Digital VRMs can adjust their settings through software, support diagnostics, and improve efficiency by fine-tuning switching times. They also offer better safety and reliability, as they can detect faults and update their control software as needed.

Note: Digital VRMs may cost more at first because of software and digital parts, but they save money over time with easy updates and better diagnostics. Analog VRMs might need hardware changes and regular calibration, which can increase long-term costs.

A well-designed VRM ensures that every sensitive component receives the correct voltage, protecting devices from damage and keeping performance high. By using advanced control methods and high-quality VRM components, manufacturers can deliver a stable power supply that meets the demands of modern electronics.

VRM Applications

Computers and Motherboards

VRMs play a central role in modern computers and motherboards. They convert higher voltage rails, such as 5V or 12V from the power supply, into the precise and stable voltages that CPUs and GPUs require. Many motherboards use multiphase synchronous buck converters to distribute the current load across several phases. This design improves voltage stability and reduces ripple, which helps protect sensitive components.

Engineers often implement dynamic voltage scaling techniques, including Dynamic Voltage Scaling (DVS) and Dynamic Voltage and Frequency Scaling (DVFS). These methods allow the VRM to adjust the voltage based on the processor's workload. When the CPU or GPU works harder, the VRM increases the voltage for better performance. During idle times, it lowers the voltage to save energy. Communication between the VRM and the processor happens through VID signals, which enable real-time voltage adjustments.

VRMs can appear as discrete components on the motherboard, as separate modules, or even integrated directly into the CPU or GPU package. For example, Intel’s Haswell processors use a Fully Integrated Voltage Regulator (FIVR) to manage power internally. High-performance GPUs often require VRMs with heat sinks because they generate significant heat during operation.

Tip: Multiphase VRMs help balance the current load, which improves energy efficiency and keeps the system cool.

Electronics and Industry

VRMs have become essential in many industries beyond personal computers. The automotive sector, especially electric and autonomous vehicles, relies on VRMs for efficient power management. Electric vehicles use VRMs to handle complex power needs in electric drivetrains, battery management, and advanced driver-assistance systems. The integration of new materials like silicon carbide (SiC) and gallium nitride (GaN) has improved VRM efficiency and power density, which is critical for electric vehicles and compact devices.

IoT devices in smart homes, factories, and telecommunications also depend on VRMs. These devices need reliable power supply and energy management to operate efficiently. As the number of IoT devices grows, the demand for advanced VRMs increases. Power management ICs combined with VRMs help optimize energy use and reduce heat, supporting reliable operation in emerging technologies.

The global market for VRMs continues to grow. Experts project the market to reach over USD 8 billion by 2033, driven by the expansion of electric vehicles and IoT devices. Regulatory pressure for energy efficiency and sustainability also encourages innovation in VRM technology.

Note: The Asia Pacific region leads the VRM market due to strong demand in automotive and telecommunications industries.

Importance of Voltage Regulation

System Stability

A VRM plays a vital role in keeping electronic systems stable. When a device receives a steady voltage, it can perform tasks without interruption. If the voltage changes too much, the system may crash or freeze. Sensitive devices like computers, medical equipment, and telecom systems need a stable voltage to work correctly. Low-quality power supplies that lack proper VRMs often cause instability and unexpected shutdowns.

-

Voltage fluctuations can lead to system crashes or hardware damage.

-

Devices such as computers and medical equipment are especially sensitive to unstable voltage.

-

Poor quality power supplies result in instability, crashes, and even component failure.

-

High-quality power supplies with good VRMs ensure reliable performance and protect hardware.

-

Inefficient power supplies generate extra heat and unstable voltage, which shortens the life of the system.

The table below shows how poor voltage regulation affects different parts of a system:

| Consequence Category | Explanation | Example/Impact |

|---|---|---|

| System Instability | Voltage fluctuations cause unstable system conditions and voltage collapse, risking outages. | Under-voltage during peak load can trip protective devices, destabilizing the power grid. |

| Hardware Damage & Safety Hazards | Over-voltage or under-voltage leads to overheating, insulation failure, and fire hazards. | Transformers exposed to over-voltage suffer insulation degradation and increased failure risk. |

| Reduced Equipment Efficiency | Operating outside optimal voltage reduces efficiency and lifespan, increasing maintenance. | Induction motors lose efficiency and have higher losses under poor voltage regulation. |

| Increased Energy Losses | Poor regulation causes higher I²R losses in transmission lines, reducing overall efficiency. | Long-distance lines without regulation mechanisms suffer significant energy losses. |

Component Protection

Stable voltage regulation protects sensitive electronics from harm. A VRM ensures that each part of a device receives the correct voltage, even when the power supply changes or the workload increases. Surge protectors and uninterruptible power supplies (UPS) also help by buffering against sudden voltage spikes and power interruptions. These devices divert extra energy away from important circuits, keeping them safe from damage.

A clean, stable voltage supply prevents hardware failures and data corruption. Devices like computers, smartphones, and audio equipment rely on this steady power to avoid malfunctions and data loss. Using pure sine wave inverters and voltage regulators reduces the risk of power surges, spikes, and electrical noise. This protection keeps internal circuits safe and extends the life of the device.

Tip: Regular inspections and backup power solutions, such as UPS units, help maintain a stable voltage and protect valuable data from unexpected power issues.

Factors Affecting VRM Performance

Component Quality

The quality of components inside voltage regulators has a direct impact on their performance and reliability. High-quality MOSFETs, inductors, and capacitors help voltage regulators maintain stable voltage and reduce the risk of failure. Poor quality or counterfeit parts often lead to early breakdowns, especially when exposed to high temperatures or electrical stress. Manufacturers test voltage regulators under different loads and conditions to ensure they deliver consistent efficiency and low noise. They measure output noise and efficiency at various current levels, not just at peak performance, to make sure the regulator works well in real-world situations.

Common failure modes in voltage regulators include:

-

Excessive heat and thermal stress from poor heat dissipation

-

Electrical overloads and voltage surges that exceed safe limits

-

Use of low-quality or counterfeit components

-

Environmental factors like humidity, dust, and corrosion

-

Manufacturing defects such as poor soldering

A voltage regulator built with high-grade parts and tested thoroughly will last longer and protect sensitive electronics better.

Design and Cooling

Design choices play a major role in how well voltage regulators perform. Proper printed circuit board (PCB) layout reduces noise, thermal stress, and unwanted interactions between components. Engineers must select the right switching frequency to balance efficiency, size, and heat. Choosing the correct inductor and capacitor values helps control ripple current and improve voltage stability.

Effective cooling is essential for voltage regulators, especially in high-power devices. Without good thermal management, heat builds up and causes failures or shortens the lifespan of the regulator. Cooling methods include heat sinks, fans, and even liquid cooling for advanced systems. Advanced thermal interface materials fill tiny gaps and improve heat transfer. System-level design, such as optimizing airflow and placing components wisely, helps prevent overheating.

Tip: Keeping voltage regulators cool and using quality parts extends their life and ensures stable voltage for all connected devices.

Environmental factors also affect performance. High temperatures increase losses and reduce efficiency, while humidity can cause corrosion. Good ventilation and protective measures, like dehumidifiers, help maintain stable operation.

Voltage regulator modules serve as the backbone of modern electronics, delivering the precise voltage that sensitive parts need. Recent research shows that VRMs prevent damage and system crashes by acting as dedicated power stations in devices like computers, phones, and servers. Users should watch for signs of VRM failure, such as excessive or insufficient voltage output and voltage fluctuations. When evaluating or troubleshooting devices, checking the VRM can help maintain reliable performance. For best results, regular inspection of power components ensures long-term device health.

FAQ

What happens if a VRM fails?

A failed VRM can cause a device to shut down, restart, or even damage sensitive components. Users may notice system instability, random crashes, or no power at all. Replacing the faulty VRM often restores normal operation.

Can users upgrade or replace VRMs on a motherboard?

Most VRMs come soldered onto the motherboard. Users cannot upgrade or replace them easily. Only skilled technicians with special tools can attempt repairs. Choosing a quality motherboard with strong VRMs helps prevent future issues.

How can someone tell if a VRM is overheating?

Signs of VRM overheating include system crashes, throttling, or a burning smell. Users may also feel excessive heat near the VRM area. Monitoring software can show high VRM temperatures.

Do all electronic devices use VRMs?

Not all devices use VRMs. Simple gadgets with fixed voltage needs may use basic regulators. Complex electronics like computers, servers, and advanced industrial equipment rely on VRMs for precise voltage control.

Written by Jack Elliott from AIChipLink.

AIChipLink, one of the fastest-growing global independent electronic components distributors in the world, offers millions of products from thousands of manufacturers, and many of our in-stock parts is available to ship same day.

We mainly source and distribute integrated circuit (IC) products of brands such as Broadcom, Microchip, Texas Instruments, Infineon, NXP, Analog Devices, Qualcomm, Intel, etc., which are widely used in communication & network, telecom, industrial control, new energy and automotive electronics.

Empowered by AI, Linked to the Future. Get started on AIChipLink.com and submit your RFQ online today!